Codigo Escuela 4.0

Article author:

Sergio PeciñaArticle published at:

November 14, 2022

Drawer menu

Calibrating the extruder is a crucial aspect of 3D printing with filament (FDM or FFF). If the extruder distributes too little material, the object will have holes or walls that are too delicate. On the other hand, if it dispenses too much material, it will create an issue called over-extrusion which will leave the piece with globs and strings, aka "Stringing".

The purpose of this calibration is to ensure correct material deposition during 3D printing.

To perform this operation you will need:

The first thing to do is to load the filament into the printer as usual. If you already have rigid material loaded in your machine just preheat the extruder.

Connect your printer to your computer via USB or WiFi to be able to send G-code commands. If your slicer does not allow this option, download and install Pronterface to do this operation.

With the help of the gauge and the marker pen, measure and mark the filament 110mm from the extruder inlet. Then send the following command from the computer: G1 E100 F100

This command orders 100mm of material to be extruded at a conservative speed to avoid any interference caused by filament tension or pressure on the hotend.

Measure from the mark to the extruder inlet area and write down the value given. If this value is 10mm, the extruder is well calibrated. But if it is different, we must recalculate the steps per millimetre of the extruder.

To obtain the current number of steps per millimetre, send the command M503 and the printer will return a series of values. Among all these, you have to locate where it says M92 and then the number that accompanies E-value (normally at the end of this line). This number is the steps per millimetre.

To calculate the new value of steps per millimetre, we have to find out how much material has actually been extruded. To do this, we subtract the measurement, we made with the calliper from 110mm.

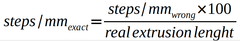

Using the following formula we will get the exact value for the extruder pitches per millimetre:

All that remains to be done now is to enter this new value in our printer. To do so, send the following command: "M92 value" (replacing value by the value obtained). Next, send the M500 command to store this value in the memory of our printer.

To check that everything has been saved correctly, turn off the printer and check again with the "M503" command to see if the new steps per millimetre have been saved correctly.

Go back to step 3 and perform this calibration again to check that it has been done properly.