Codigo Escuela 4.0

-

Product label:

TPU Flex Filament - 93A

Eolas Prints

SKU: TPU-FLX-1.75M-DGN-1KG

Increments of 1

Minimum of 1

Maximum of

Low stock

In stock, ready to ship

Sale price

S/. 134.00 PEN

-100%

Regular price

S/. 0.00 PEN

Regular price

S/. 134.00 PEN

Unit price

per

TPU Flex Filament - 93A

Sale price

S/. 134.00 PEN

Regular price

S/. 0.00 PEN

Regular price

S/. 134.00 PEN

Unit price

per

Couldn't load pickup availability

Spain & Portugal (Mainland): Order before 4PM to receive it tomorrow. Except weekends.

Rest of the world: Express shipping options available at checkout.

EU VAT Exempt: No VAT on all EU B2B orders. Please contact us.

Spain: Electronic invoicing options available via FACe. Please contact us.

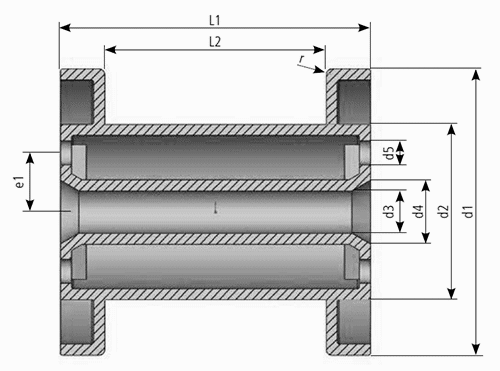

Spool dimensions

Our spools are compatible with all major 3D printer brands including Prusa, Bambu Lab (AMS & AMS Lite), Flashforge, and more. The standardised axle diameter ensures seamless integration with your existing equipment.

|

Specification |

1kg |

2kg |

5kg |

8kg |

10kg |

15kg |

20kg |

|---|---|---|---|---|---|---|---|

|

Outer Diameter (d1) |

200 mm |

300 mm |

350 mm |

335 mm |

335 mm |

335 mm |

335 mm |

|

Inner Diameter (d2) |

105 mm |

212 mm |

180 mm |

190 mm |

190 mm |

100 mm |

100 mm |

|

Hub Diameter (d3) |

52 mm |

52 mm |

52 mm |

51 mm |

51 mm |

31 mm |

31 mm |

|

Axle Diameter (d5) |

11 mm |

11 mm |

12 mm |

20 mm |

20 mm |

20 mm |

20 mm |

|

Flange Width (e1) |

44.5 mm |

44.5 mm |

44.5 mm |

70 mm |

70 mm |

70 mm |

70 mm |

|

Spool Length (l1) |

68 mm |

100 mm |

100 mm |

245 mm |

245 mm |

Variable |

Variable |

|

Winding Length (l2) |

59 mm |

90 mm |

90 mm |

220 mm |

220 mm |

Variable |

Variable |

|

Winding Volume |

1,342 cm³ |

3,220 cm³ |

6,366 cm³ |

13,147 cm³ |

6,366 cm³ |

— |

— |

|

Nominal Weight |

— |

600 gr |

600 gr |

1,050 gr |

1,050 gr |

— |

— |

Have a question?

Description

TPU Flex 93A combines exceptional flexibility with professional-grade durability in a food-safe formulation. This premium thermoplastic polyurethane filament delivers the perfect balance of elasticity and strength, with a carefully calibrated 93A Shore hardness that ensures optimal performance across diverse applications.

Technical Specifications

- Material Composition: Medical-grade thermoplastic polyurethane

- Shore Hardness: 93A (medium-soft flexibility)

- Available Diameters: 1.75mm and 2.85mm

- Certifications: Food contact safe

- Environmental Profile: Recyclable

Performance Characteristics

- Exceptional resilience and compression recovery

- Superior wear resistance in high-friction applications

- Outstanding oil and chemical resistance

- Excellent impact absorption properties

- Consistent dimensional stability

- Precise layer adhesion with minimal warping

- Reliable shape retention after repeated stress

Application Versatility

- Culinary: Food preparation tools, custom cookie cutters, kitchen accessories

- Consumer Products: Protective cases, wearable components, grip surfaces

- Automotive: Gaskets, seals, vibration dampeners, interface components

- Medical: Orthopaedic supports, prosthetic elements, comfort-enhancing products

- Industrial: Custom gaskets, protective covers, flexible connectors

- Prototyping: Functional flexible parts, product validation models

Processing Recommendations

- Compatible with direct drive extruder systems

- Optimal print speed: 20-30mm/s

- Recommended temperature range: 220-235°C

- Heated bed recommendation: 50-60°C

- Enhanced results with enclosed printing environment

Unique Advantages

- Food-safe formulation for direct food contact applications

- Long-term flexibility without brittleness degradation

- Combined elasticity and structural integrity

- Professional-grade print quality

- Eco-friendly composition

Download print profiles

Achieve superior 3D printing results with our custom print profiles, expertly calibrated for Eolas Prints filaments. These profiles are meticulously developed to ensure optimal performance, saving you time on configuration and testing. By using our dedicated print profiles, you can expect consistent quality and reliability with every print.

Bambu Studio

Prusa Slicer

Idea Maker

Ultimaker Cura

Shipping policy

When do you ship?

We ship daily from stock. Orders placed after 1PM and 4PM on Fridays are shipped on Monday.

| Spain & Portugal | Orders placed before 4PM CET are shipped the same day. |

| Rest of the world | Orders placed before 1PM CET are shipped the same day. |

How do you ship?

Shipping times and options are available at checkout.

| Spain & Portugal |

GLS: Next Business Day UPS: 1 - 2 Business Day |

| Rest of Europe |

UPS Standard: 2 - 5 Business Days UPS Worldwide Saver: 1 - 2 Business Days UPS Express: 1 - 2 Business Days (Before 2PM) |

| North America |

UPS Worldwide Saver: 1 - 2 Business Days UPS Express: 1 - 2 Business Days (Before 2PM) |

| South America |

UPS Worldwide Saver: 2 - 5 Business Days |

| Middle East |

UPS Worldwide Saver: 1 - 2 Business Days UPS Express: 1 - 2 Business Days (Before 2PM) |

| Asia |

UPS Worldwide Saver: 5 - 7 Business Days |

| Australia & New Zealand |

UPS Worldwide Saver: 5 - 7 Business Days UPS Express: 3 - 5 Business Days (Before 2PM) |

How about Taxes & Duties?

| Any taxes and custom duties are automatically calculated at checkout. |

Our Guarantee

Specifications

Material

Polyurethane elastomer

Density

1.21 g/cm3

Hardness

93A

Features

Chemical resistance, Polyester based, 500% Elongation @ break, and Food contact safe.

Heat deflection temperature - HDT

N/A

Vicat softening temperature

N/A

Print temperature

195 - 235 °C

Bed temperature

0 - 50 °C

Print speed

20 - 65 mm/s

Nozzle

0.15 - 1.2 mm

Cooling

0 - 100 %

Chamber

Not Mandatory

Dry box

Recommended

Adhesive

Not mandatory (Use one for increased adhesion)

Diameter tolerance

± 0.08 mm

Compatibility

FDM (Fused Deposit Modelling) & FFF (Fused Filament Fabrication)

Why Choose Us?

-

Worldwide Shipping

-

Premium Quality

-

Technical Support

-

30 Days Returns Policy

-

100% Secure Payments